Old Wiring Repair & Rewire

Does your home have knob and tube wiring, aluminum branch electrical wiring, or an ungrounded two wire home electrical wiring system? Are you in the process of selling your home and you need to make electrical safety corrections is pending the sale? Or you may have had some fire, water, or other structural damage that will require some new home wiring. Whether you are repairing damaged electrical systems or need to upgrade your old house wiring, Roberts Electrical can take care of all your electrical rewiring needs.

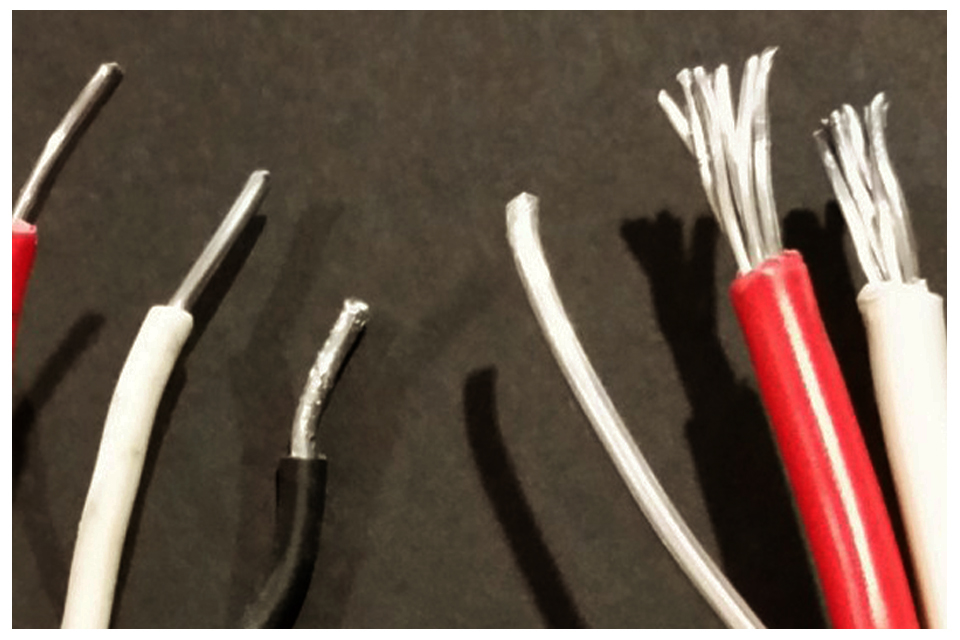

Aluminum Wiring

Aluminum was the type of wiring used in the 1960s and 1970s as a cheap substitute to copper wiring. Aluminum wiring is not safe. There are three hazards caused by aluminum wiring:

Oxidization. When oxidize (rust) forms on aluminum, it increases the wire’s resistance and impedes the flow of electricity. Although copper wiring also rusts, the green copper oxide that forms is electrically conductive. However, when the white oxide on aluminum wiring forms, it interferes with the flow of electricity, and causes overheating.

Softness. Aluminum is a much softer metal than copper. It can be easily nicked or cut. The damaged wire creates local hot spots.

High thermal expansion. Aluminum wiring has a tendency to change shape at the terminal screws when current flows through it and thus become loose or creep off.

Danger signs of aluminum wiring that may have connection problems:

-

sparks coming from receptacles or switches

-

unusually warm or warped outlets and switch cover plates

-

strange odors in the area of receptacles and switches

-

light bulbs that burn out quickly

-

lights that flicker

-

circuit breakers that trip for no reason

Aluminum wiring is not safe for a do-it-yourselfer. Hire only a licensed electrician to work on circuits with aluminum wiring. The safest solution to the problems and hazards associated with aluminum wiring: replace it with copper wiring– and allow experienced, licensed electricians to do the job.

Call Today for a FREE Quote! (705) 561-9339

Knob & tube

Knob-and-tube (K&T) wiring was an early standardized method of electrical wiring in buildings, in common use in North America from about 1880 to the 1940s. The system is considered obsolete and can be a safety hazard, although some of the

fear associated with it is undeserved.

Inspectors should always disclaim knob-and-tube wiring during their inspections.

Facts About Knob & Tube Wiring:

-

It is not completely dangerous. The dangers from this system arise from its age, improper modifications, and situations where building insulation envelops the wires.

-

It has no ground wire and thus cannot service any three-pronged appliances.

-

While it is considered obsolete, there is no code that requires its complete removal.

-

It is treated differently in different jurisdictions. In some areas, it must be removed at all accessible locations, while others require that it not be installed in new construction. Inspectors should be sure to know the codes in the jurisdictions in which they operate.

-

It is not permitted in any new construction.

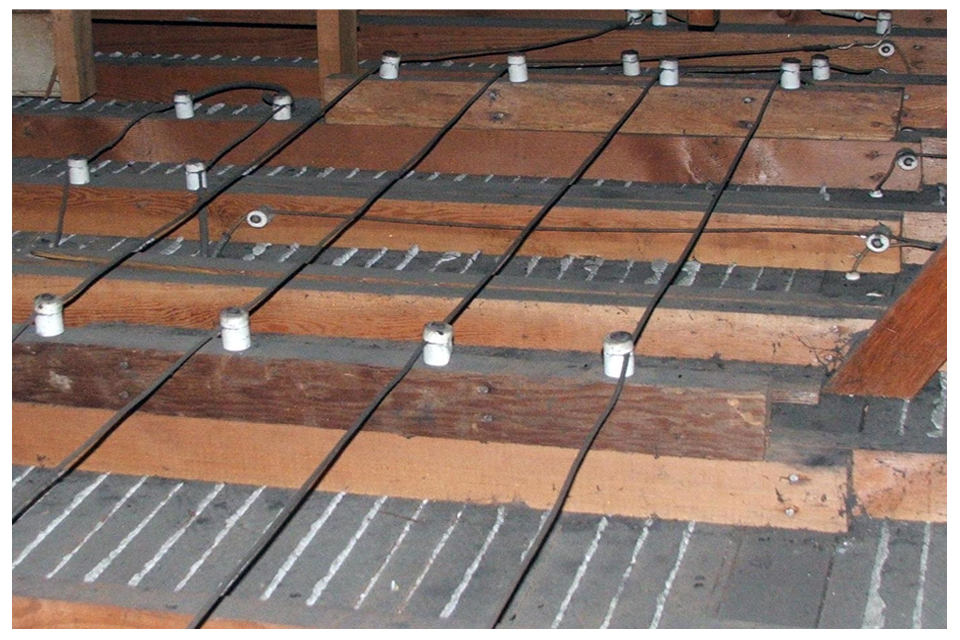

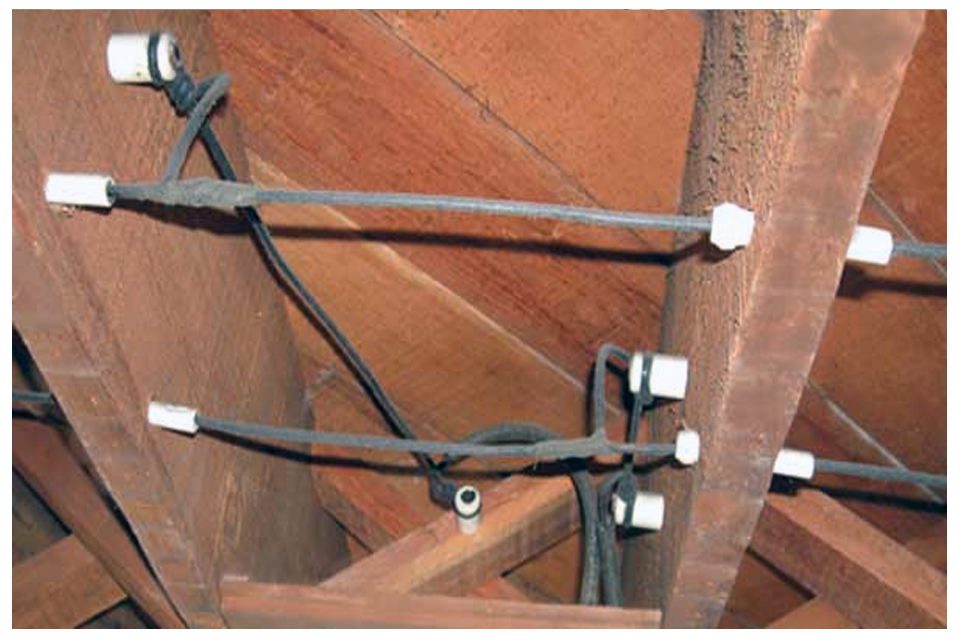

How Knob-and-Tube Wiring Works:

K&T wiring consists of insulated copper conductors passing through drill-holes in lumber framing via protective porcelain

insulating tubes. They are supported along their length by nailed-down porcelain knobs. Where wires enter a wiring device,

such as a lamp or switch, or were pulled into a wall, they are protected by flexible cloth or rubber insulation called “loom.”

Advantages of Knob-and-Tube Wiring:

-

K&T wiring has a higher ampacity than wiring systems of the same gauge. The reason for this is that the hot and neutral wires are separated from one another, usually by 4 to 6 inches, which allows the wires to dissipate heat into free air.

-

K&T wires are less likely than Romex cables to be punctured by nails because K&T wires are held away from the framing.

-

The porcelain components have an almost unlimited lifespan.

-

The original installation of knob-and-tube wiring is often superior to that of modern Romex wiring. K&T wiring installation requires more skill to install than Romex, and for this reason, unskilled people rarely ever installed it.

Problems Associated with K&T Wiring:

-

Unsafe modifications are far more common with K&T wiring than they are with Romex and other modern wiring systems. Part of the reason for this is that K&T is so old that more opportunity has existed for improper modifications.

-

The insulation that envelopes the wiring is a fire hazard.

-

It tends to stretch and sag over time.

-

It lacks a grounding conductor. Grounding conductors reduce the chance of electrical fire and damage to sensitive equipment.

-

In older systems, wiring is insulated with varnish and fibrous materials that are susceptible to deterioration.

Compared with modern wiring insulation, K&T wiring is less resistant to damage. K&T wiring insulated with cambric and

asbestos is not rated for moisture exposure. Older systems contained insulation with additives that may oxidize copper wire.

Bending the wires may cause insulation to crack and peel away.

K&T wiring is often spliced with modern wiring incorrectly by amateurs. This is perhaps due to the ease by which K&T wiring is

accessed.

Building Insulation:

K&T wiring is designed to dissipate heat into free air, and insulation will disturb this function. Insulation around K&T wires will cause heat to build up, and this creates a fire hazard. The 2008 National Electrical Code (NEC) requires that this wiring system not be covered by insulation. Specifically, it states that this wiring system should not be in hollow spaces of walls, ceilings and

attics where such spaces are insulated by loose, rolled or foamed-in-place insulating material that envelops the conductors.

Local jurisdictions may or may not adopt the NEC’s requirement. The California Electrical Code, for instance, allows insulation to be in contact with knob and tube wiring, provided that certain conditions are met, such as, but not limited to the following:

-

A licensed electrical contractor must certify that the system is safe.

-

The certification must be filed with the local building department.

-

Accessible areas where insulation covers the wiring must be posted with a warning sign. In some areas, this sign must be in Spanish and English.

-

The insulation must be non-combustible and non-conductive.

-

Normal requirements for insulation must be met.

Modifications:

When K&T wiring was first introduced, common household electrical appliances were limited to little more than toasters, tea

kettles, coffee percolators and clothes irons. The electrical requirements of mid- to late-20th century homes could not have

been foreseen during the late 18th century, a time during which electricity, to many, was seen as a passing fad. Existing K&T systems are notorious for modifications made in an attempt to match the increasing amperage loads required by televisions,

refrigerators, and a bunch of other electrical appliances. Many of these attempts were made by insufficiently trained

handymen, rather than experienced electricians, whose work made the wiring system vulnerable to overloading.

-

Many homeowners adapted to the inadequate amperage of K&T wiring by installing fuses with resistances that were too high for the wiring. The result of this modification is that the fuses would not blow as often and the wiring would suffer heat damage due to excessive amperage loads.

-

It is not uncommon for inspectors to find connections wrapped with masking tape or Scotch tape instead of electrical tape.

K&T Wiring and Insurance:

Many insurance companies refuse to insure houses that have knob and tube wiring due to the risk of fire. Exceptions are sometimes made for houses where an electrical contractor has deemed the system to be safe.

Advice for those with K&T wiring:

-

Have the system evaluated by a qualified electrician. Only an expert can confirm that the system was installed and modified correctly.

-

Do not run an excessive amount of appliances in the home, as this can cause a fire.

-

Where the wiring is brittle or cracked, it should be replaced. Proper maintenance is crucial.

-

K&T wiring should not be used in kitchens, bathrooms, laundry rooms or outdoors. Wiring must be grounded in order to be used safely in these locations.

-

Rewiring a house can take weeks and cost thousands of dollars, but unsafe wiring can cause fires, complicate estate transactions, and make insurers skittish.

-

Homeowners should carefully consider their options before deciding whether to rewire their house.

-

The homeowner or an electrician should carefully remove any insulation that is found surrounding K&T wires.

-

Prospective home buyers should get an estimate of the cost of replacing K&T wiring. They can use this amount to negotiate a cheaper price for the house.

In conclusion, knob-and-tube wiring is likely to be a safety hazard due to improper modifications and the addition of building insulation. Inspectors need to be wary of this old system and be prepared to inform their clients about its potential dangers.

Call Today for a FREE Quote! (705) 561-9339

If you think your house needs a rewire give us a call at (705) 561-9339 to perform an Inspection Report on your house wiring.

What To Look For

-

Signs of burning around electrical outlets

-

excessive use of adaptors and extension cords.

-

Does the fuse box look old?

-

Use of fuse wire in the fuse box.

-

No rewire in past 25 years – some electricians may state a different time period.

-

Black rubber jacket on wiring.

-

Large ceramic type fuses in fuse box.

-

Fabric coated electrical wiring.

-

Twisted flex on ceiling lights.

-

Electrical outlets mounted on skirting base board.

Faults That Suggest A Rewire Is Needed

-

Constantly tripping RCDs

-

Unexplained random electrical problems.

-

Constantly blowing fuses

-

Same fuse keeps blowing

-

Flickering lights

-

Electrical are sockets hot.